Product Parameter:

Water supply HDPE pipe is a type of flexible plastic pipe used for municipal water supply and drainage systems, water treatment pipeline systems, industrial water supply and drainage systems,rural or agriculture irrigation systems etc, made from thermoplastic high density polyethylene(PE100, PE4710),100% new food grade virgin material imported from Borealis, non-toxic,green and safe for potable water transfer, excellent flexibility makes PE pipe can be coiled to make trench-less installation safer,butt welding joint.biggest size reached 1200mm.

HIGH TOUGHNESS

ZHSU HDPE water pipe’s elongation at break exceed 500%, have strong adaptability to uneven

settlement of pipe foundation, with excellent seismic capacity.

NON-TOXIC AND HEALTH

HDPE pipe material is non-toxic, green and safe, there is no heavy metal additives added, food grade polyethylene virgin material is used to produce HDPE water pipes, they are safe for potable water transfer.

EXCELLENT FLEXIBILITY

Excellent flexibility makes PE pipe can be coiled to make trench-less installation safer,supply HDPE pipes with long length to avoid a large number of joints and fittings usage, increased cost-effectiveness

LEAK FREE JOINT

HDPE pipes can be jointed by butt welding or electrofusion welding usually, the joint strength is higher than the pipe body, with resistance to water hammer pressure,greatly improves the safety and reliability of water supply.

CHEMICAL CORROSION RESISTANCE

HDPE pipe can be resistant to a variety of chemical corrosion,chemicals in the soil will not cause degradation of HDPE pipe, polyethylene is the electric insulator, it will not rot and rust, in addition it will not promote algae and bacteria growth.

SPECIFICATIONS

Material : High density polyethylen PE100/ PE4710 with black colour

Size : DN20mm ~ DN1200mm

Pressure : PN16/SDR11 ~ PN6/SDR26

Length : 4 meter / pcs, 3 meter/pcs , 5.8 meter/pcs or 100 meter per coil

Standard : ISO 4427,DIN 8074/75, GB/T13663-2000

Joint : HDPE pipe jointed by butt welding

| Size (mm) | PN16 | PN12.5 | PN10 | PN8 | ||||

| Thickness (mm) | Weight (kg/meter) | Thickness (mm) | Weight (kg/meter) | Thickness (mm) | Weight (kg/meter) | Thickness (mm) | Weight (kg/meter) | |

| 20 | 2.3 | 0.135 | ||||||

| 25 | 2.3 | 0.173 | ||||||

| 32 | 3 | 0.289 | 2.4 | 0.237 | ||||

| 40 | 3.7 | 0.446 | 3 | 0.364 | ||||

| 50 | 4.6 | 0.693 | 3.7 | 0.553 | 3 | 0.455 | ||

| 63 | 5.8 | 1.051 | 4.7 | 0.868 | 4 | 0.759 | ||

| 75 | 6.8 | 1.469 | 5.6 | 1.231 | 4.5 | 1.005 | ||

| 90 | 8.2 | 2.124 | 6.7 | 1.767 | 5.4 | 1.447 | 4.3 | 1.167 |

| 110 | 10 | 3.167 | 8.1 | 2.614 | 6.6 | 2.161 | 5.3 | 1.757 |

| 125 | 11.4 | 4.101 | 9.2 | 3.374 | 7.4 | 2.756 | 6 | 2.261 |

| 140 | 12.7 | 5.12 | 10.3 | 4.23 | 8.3 | 3.461 | 6.7 | 2.828 |

| 160 | 14.6 | 6.722 | 11.8 | 5.538 | 9.5 | 4.527 | 7.7 | 3.714 |

| 180 | 16.4 | 8.496 | 13.3 | 7.021 | 10.7 | 5.736 | 8.6 | 4.668 |

| 200 | 18.2 | 10.478 | 14.7 | 8.626 | 11.9 | 7.088 | 9.6 | 5.788 |

| 225 | 20.5 | 13.275 | 16.6 | 10.955 | 13.4 | 8.979 | 10.8 | 7.326 |

| 250 | 22.7 | 16.339 | 18.4 | 13.494 | 14.8 | 11.023 | 11.9 | 8.972 |

| 280 | 25.4 | 20.478 | 20.6 | 16.921 | 16.6 | 13.846 | 13.4 | 11.313 |

| 315 | 28.6 | 25.938 | 23.2 | 21.437 | 18.7 | 17.546 | 15 | 14.25 |

| 355 | 32.2 | 32.914 | 26.1 | 27.183 | 21.1 | 22.31 | 16.9 | 18.094 |

| 400 | 36.3 | 41.807 | 29.4 | 34.502 | 23.7 | 28.241 | 19.1 | 23.038 |

| 450 | 40.9 | 52.985 | 33.1 | 43.698 | 26.7 | 35.79 | 21.5 | 29.173 |

| 500 | 45.4 | 65.356 | 36.8 | 53.978 | 29.7 | 44.231 | 23.9 | 36.032 |

| 560 | 50.8 | 81.912 | 41.2 | 67.685 | 33.2 | 55.384 | 26.7 | 45.09 |

| 630 | 109.6 | 378.5 | 46.3 | 85.579 | 37.4 | 70.183 | 30 | 56.999 |

| 710 | 42.1 | 89.041 | 33.9 | 72.579 | ||||

| 800 | 47.4 | 112.964 | 38.1 | 91.922 | ||||

| 900 | 42.9 | 116.436 | ||||||

| 1000 | 59.3 | 176.646 | 47.7 | 151.6 | ||||

| 1200 | 67.9 | 243.9 | 57.2 | 206.997 | ||||

APPLICATION

1: Municipal water supply,water mains,sewer mains, rural irrigation,

2: Food,Chemical industry

3: Replacement of cement pipe,cast iron pipe and steel pipe

4: Greenbelts irrigation,farmland irrigation

5: Other applications such as power engineering,communications, deep sea farming etc

TEST & INSPECTION

| TEST | Unit | Test Conditions | Index | ||

| Elongation Rate | % | ≥ 350 | |||

| Longitudinal Reversion | % | 110℃ | ≤ 3 | ||

| Oxidation Induction Time | min | 200℃ | ≥ 20 | ||

| Hydro-static Pressure (PE100) | Mpa | 20℃ | 100h | Stress 12.4Mpa | No crack,no leakage |

| 80℃ | 165h | Stress 5.5 Mpa | |||

| 80℃ | 1000h | Stress 5.0 Mpa | |||

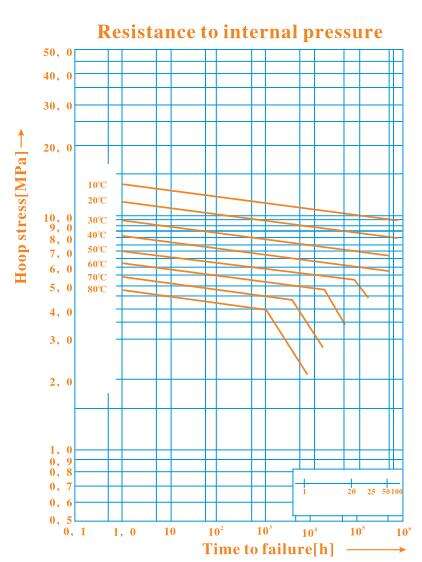

HYDROSTATIC PRESSURE PERFORMANCE

HDPE PIPE BUTT FUSION

HDPE pressure piping system use butt fusion to connect for big size, socket fusion for small size

Butt fusion is using welding machine to heat pipe at both ends ( the temperature is 210 + - 10℃)until the pipe end melted, it should adhesion the HDPE pipe end rapidly and keep a certain pressure, after cooling, all the procedures have been finished, the following table is the reference for the welding procedures.

| Wall Thickness (mm) | Technology | |||

| First: Pre-heating | Second: Fusion | Third: Switch | Fourth: Connection | |

| Pre-heating pressure:0.15Mpa | Pressure: 0.01Mpa | Max:Switch | Welding pressure :0.15Mpa | |

| Pre-heating temperature:210℃ | Pre-heating temperature:210℃ | Permission Time (s) | Cooling Time (s) | |

| Pre-heating Overlapping high | Heating Time (s) | |||

| 2-3.9 | 0.5 | 30-40 | 4 | 4-5 |

| 4.3-6.9 | 0.5 | 40-70 | 5 | 6-10 |

| 7.0-11.4 | 1 | 70-120 | 6 | 10-16 |

| 12.2-18.2 | 1 | 120-170 | 8 | 17-24 |

| 20.1-25.5 | 1.5 | 170-210 | 10 | 25-32 |

| 28.3-32.3 | 1.5 | 210-250 | 12 | 33-40 |