Nein... Auch ich nicht. Nun, hast du jemals eine dieser großen Wasserleitungen gesehen, die Wasser von einem Ort zum anderen transportieren? Diese Leitung ist ein HD-Bewässerungsfilter für Swimmingpools. HDPE bedeutet hochdichte Polyethylen. Dieses Kunststofftyp ist sehr robust, er biegt sich leicht anstatt zu brechen. Das macht HDPE zu einem hervorragenden Material für Rohre. Es kann viel Druck aushalten, ohne zu reißen oder durch Chemikalien im Wasser oder Gas zerstört zu werden. HDPE-Rohre sind in verschiedenen Größen und Formen erhältlich. Sie werden verwendet, um eine Vielzahl von Dingen zu transportieren, von Trinkwasser bis hin zu Gas versorgtem Heizlufthaushalt und Abwasserentsorgung in Häusern und Gebäuden.

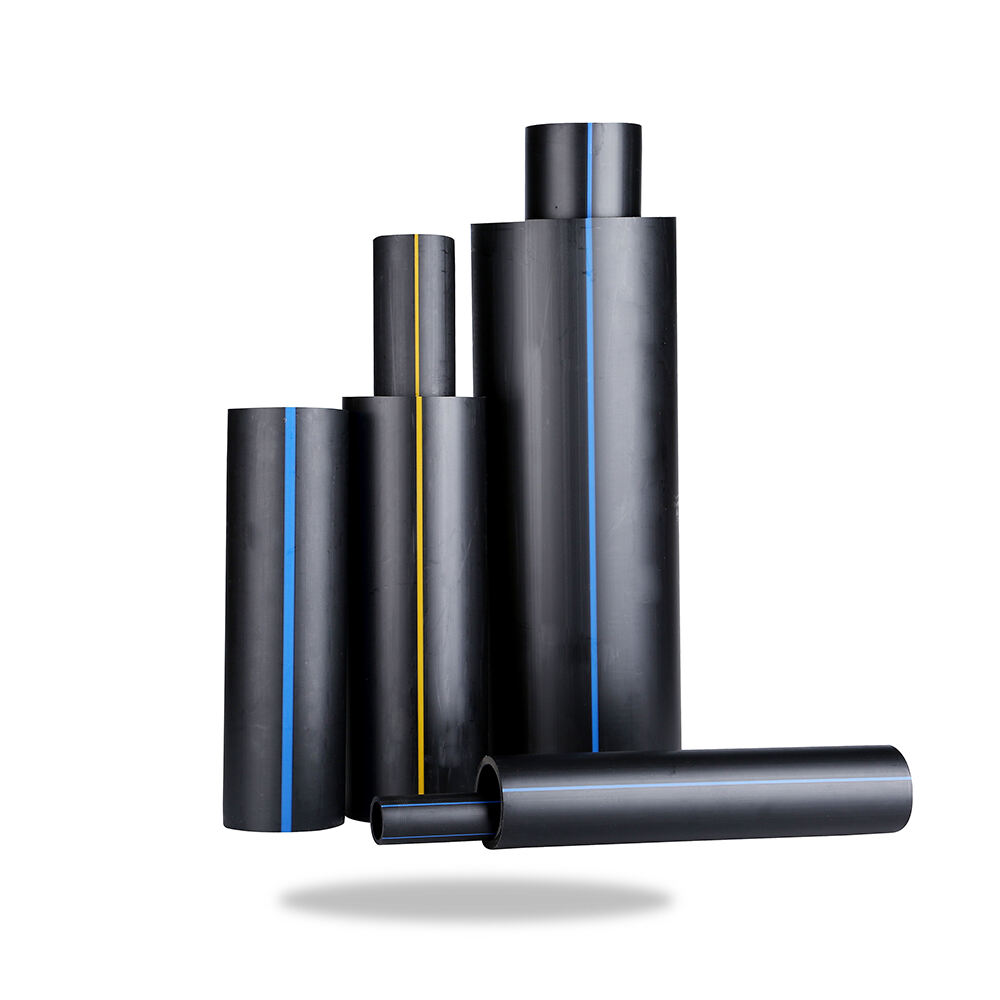

Diese HDPE-Rohre verändern tatsächlich die heutigen Methoden zur Errichtung und Verwaltung unserer Infrastrukturen, Gebäude, Straßen usw. Da HDPE-Rohre sehr haltbar und langlebig sind, ist es kein Wunder, dass viele Bauunternehmer auf sie zurückgreifen, wenn sie ihre Projekte starten. Element 2: Einfache Installation, was ein großer Vorteil bei der Nutzung von HDPE-Rohren ist. Im Gegensatz zu älteren Rohrarten haben HDPE-Rohre weniger Anschlüsse oder Fügepunkte. Man möchte möglicherweise weniger Fügepunkte sehen (sie sind zwar sehr stabil, aber dies ist ein weiterer möglicher Punkt für Versagen), schließlich könnte man Wasser oder Gas im Rohr transportieren und weniger = besser. Darüber hinaus sind HDPE-Rohre leichtgewichtig und viel einfacher zu handhaben, sodass sie problemlos an den Bauplatz gebracht werden können, was die Transportkosten senkt. All diese Vorteile führen letztlich zu langfristigen Einsparungen, da diese HDPE-Rohre weniger Reparaturen oder andere Wartungsarbeiten benötigen.

Die Verwendung von HDPE-Rohren beim Bau von Häusern hinterlässt einen anderen Eindruck, sie bauen für den Planeten. Eine interessante Eigenschaft von HDPE-Rohren ist, dass sie aus recycelbarem Material hergestellt werden. Die Tatsache, dass sie recycelbar sind, bedeutet auch, dass, falls sie jemals nicht mehr benötigt werden, weil etwas als überflüssig oder veraltet wird – was theoretisch im Bauwesen passieren kann! – sie nicht auf eine Deponie kommen, sondern stattdessen als Rohmaterial wiederverwendet werden. Das macht sie umweltfreundlich, da sie aus recycelbaren Materialien hergestellt werden. HDPE-Rohre produzieren außerdem weniger Kohlendioxid bei der Herstellung als andere Materialien wie Stahl. Allein durch die geringeren Emissionen, die durch die Verwendung dieser energieeffizienteren Ressource entstehen, wird die Verschmutzung der Erde reduziert. Zudem ist HDPE robust und widerstandsfähig (HDPE übertreffen lebensdauerbezogene Effizianzforderungen für Belegrohre), wodurch es besser als traditionelle Materialien allen Naturkatastrophen trotzt. Das bedeutet auch, dass sie nicht so häufig repariert oder ersetzt werden müssen, was weniger verschwendete Ressourcen bedeutet und HDPE zu einer nachhaltigeren Lösung für die langfristige Erhaltung unserer Umwelt macht.

Die Vorteile, die sie bieten, sind, dass HDPE-Rohre wirklich stark sind und großen Druck aushalten können. Sie sind rostresistent und brechen nicht leicht, selbst wenn sie bei rauem Wetter oder Chemikalien eingesetzt werden.ßerdem können diese Rohre bei extremen Temperaturen, sowohl heiß als auch kalt, gefunden werden. Diese Flexibilität und Dauerhaftigkeit machen diese Rohre vielseitig für verschiedene Anwendungen. Zum Beispiel eignen sie sich gut zum Aufbewahren von Wasser und Gas sowie zur Porosität von Pflastersteinen, die Drainagesysteme unterstützen, die sympatische Wasser entfernen. HDPE-Röhren werden sogar bei schweren Arbeiten wie im Bergbau und in der Offshore-Industrie eingesetzt, aufgrund ihrer Widerstandsfähigkeit unter sehr harten Bedingungen. Diese Rohre werden auch weitverbreitet verwendet, da Ingenieure und Baufirmen ihnen vertrauen, dass sie angemessen funktionieren, unabhängig von den Umweltbedingungen, unter denen sie eingesetzt werden.

In diesem Fall, warum verwenden Bauträger und Ingenieure HDPE-Rohre anstatt anderer Materialien? Die Antwort ist, dass HDPE-Rohre stark, flexibel und robust sind. Da diese Produkte einfach zu installieren sind, sparen sie Zeit sowie Arbeitskosten. Es stimmt auch, dass sie nicht häufig repariert oder aktualisiert werden müssen, was bedeutet, dass Sie Geld sparen können. Einer der größten Faktoren bei der Wahl von HDPE-Rohren, die so vielen Menschen gefallen, ist, dass sie umweltfreundlich sind. Auf der Suche nach Wegen, unser Erdreich zu erhalten, wird die Verwendung von Materialien, die sanfter mit ihm umgehen, zunehmend zur Priorität. HDPE-Rohre werden in Anwendungen eingesetzt, in denen verschiedene andere Formen von Rohrleitungen benötigt werden, darunter das Transportieren von Wasser und Gas sowie die Abwasserentsorgung mit einem angemessenen Entsorgungssystem. Sie werden auch für einige der härtesten Arbeiten im Bergbau und in der Offshore-Arbeit vertraut, aufgrund ihrer erstaunlichen Leistung und Haltbarkeit unter harten Bedingungen.

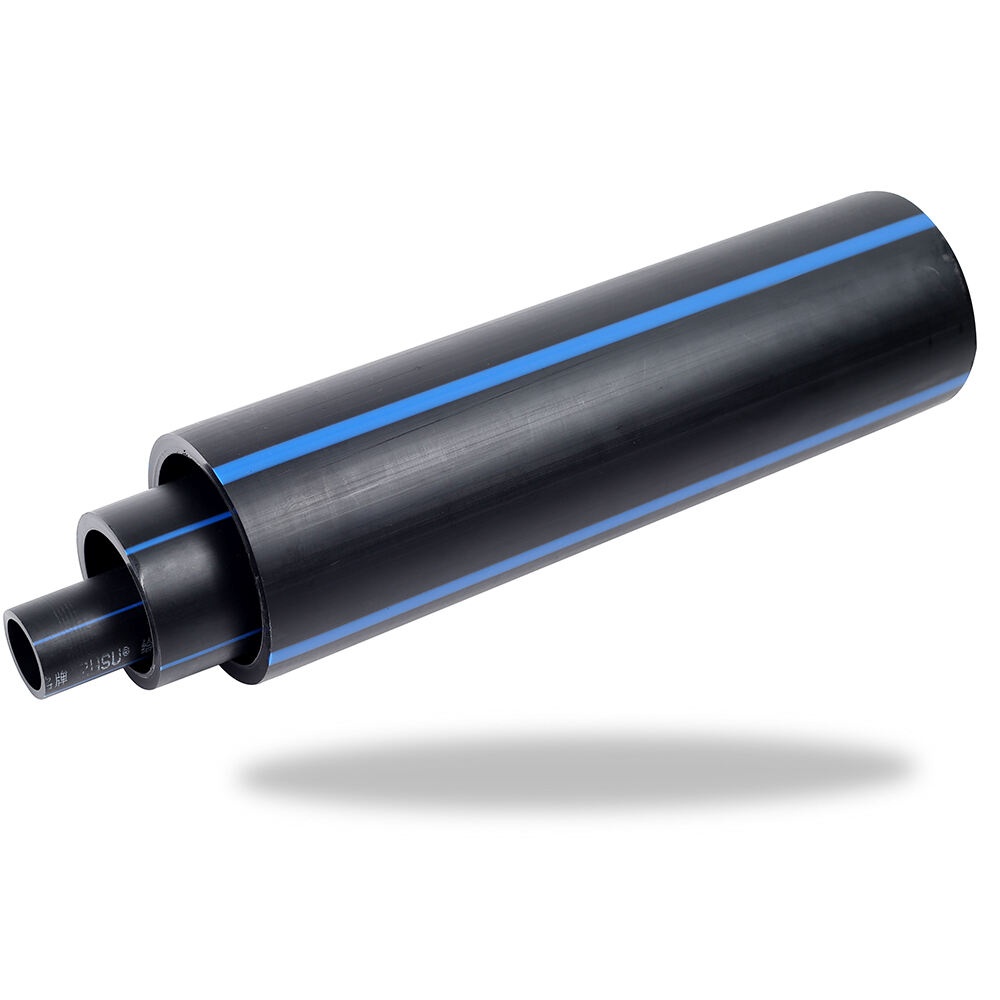

Bei Shanghai Zhongsu Pipe Co Ltd ist Qualität unser Hauptanliegen. Wir unterhalten ein hdpe-rohr-zertifiziertes nationales Labor, in dem wir während des gesamten Fertigungsprozesses strenge Inspektionen durchführen. Von der Beschaffung roher Materialien bis hin zu den gelieferten Produkten wird jeder Schritt nach internationalen Standards wie ISO15874, ISO 16962, ISO 4427/4437 sowie DIN 8077/8078/8074/8075 durchgeführt. Unsere Produkte erfüllen die höchsten Qualitäts- und Sicherheitsanforderungen.

Im Jahr 2004, mit einem autorisierten Kapital von 1,01 Milliarden RMB, hat sich Shanghai Zhongsu Pipe Co., Ltd. spezialisiert auf die Herstellung einer breiten Palette an hdpe Rohren, Kunststoffrohren und -verbindungen. Unsere Produktpalette umfasst PPR Anschlussrohre und -rohre, die antibakteriell sowie UV-beständig sind, sowie PP RCT Rohre und Verbindungen und HDPE Rohre und Verbindungen. Wir sind dem innovativen Denken und der Forschung und Entwicklung verpflichtet, indem wir kontinuierlich unser Produktangebot erweitern, um den sich ändernden Bedürfnissen unserer Kunden gerecht zu werden.

hdpe Rohr ist eine der beliebtesten Marken in China und wurde als hochtechnologisches Unternehmen in Shanghai anerkannt. Wir wurden durch das CNAS-zertifizierte Laborzertifikat, ISO14001, ISO9001, ISO45001, CE-Zertifikat und eine Vielzahl von CE-Zertifikaten für Gas- und Wasserleitungsrohre zertifiziert. Diese Auszeichnungen spiegeln unsere Hingabe an Qualität in der Produktion sowie Umweltverantwortung und Produktsicherheit wider.

Unsere Produktionsanlage, gelegen im hdpe-Rohrwerk von Shanghai, umfasst 70.500 Quadratmeter und ist mit der modernsten Produktionsausrüstung, Prüfgeräten und internationalen Standards ausgestattet. Mit einer Jahresproduktionskapazität von 3.000 Tonnen decken wir eine Vielzahl an Kundenbedarf ab und gewährleisten eine schnelle Markteinführung ohne Kompromisse bei der Qualität. Wir freuen uns, weltweit über 3.000 Kunden bedient zu haben und verlässliche Rohrlösungen entsprechend den spezifischen Anforderungen jedes Kunden anzubieten.