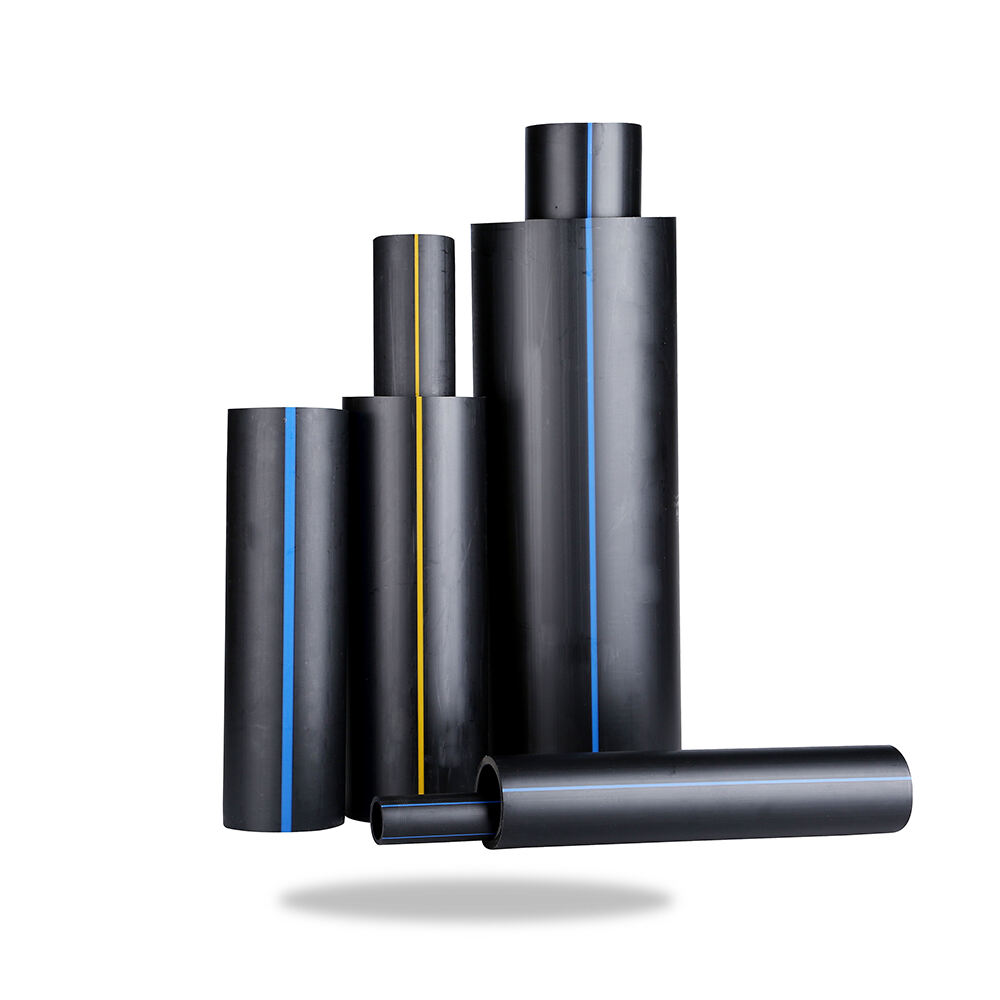

Known for its remarkable strength and longevity, the 100mm HDPE pipe is a material which works excellent in urban water transmission line as well waste purposes. The pipe is constructed from high-density polyethylene for durability and a long service life. And with that flexibility, it can be easily manipulated and formed into place thus being a flexible solution for many settings/scenarios.

Water and other liquids flow through the 100mm HDPE pipe, making these conduits popular in residential as well as commercial and industrial areas. And it is very strong and can bear high pressure easily. In addition to this, it is chemical and UV resistant so you can feel confident knowing these selections are built to last.

For the material of 100mm HDPE pipe, it has been used frequently for water distribution systems because this piping would be tough and have enough load-bearing ability to bear higher pressures. In view of this, its anti-oxidation nature ensures that there will always be clean water from the source to a different point on earth.

The installation of a 100mm HDPE pipe, which can weigh up to several hundred kilograms per metre in diameter, is no walk in the park due to its heavier nature. The process begins with unboxing the pipe and continues with careful cutting, fitting tightly to each other using custom-made tools. A snug fit and tight joints are necessary to make the installation right. Filling the pipe with water once in place confirms that all is well.

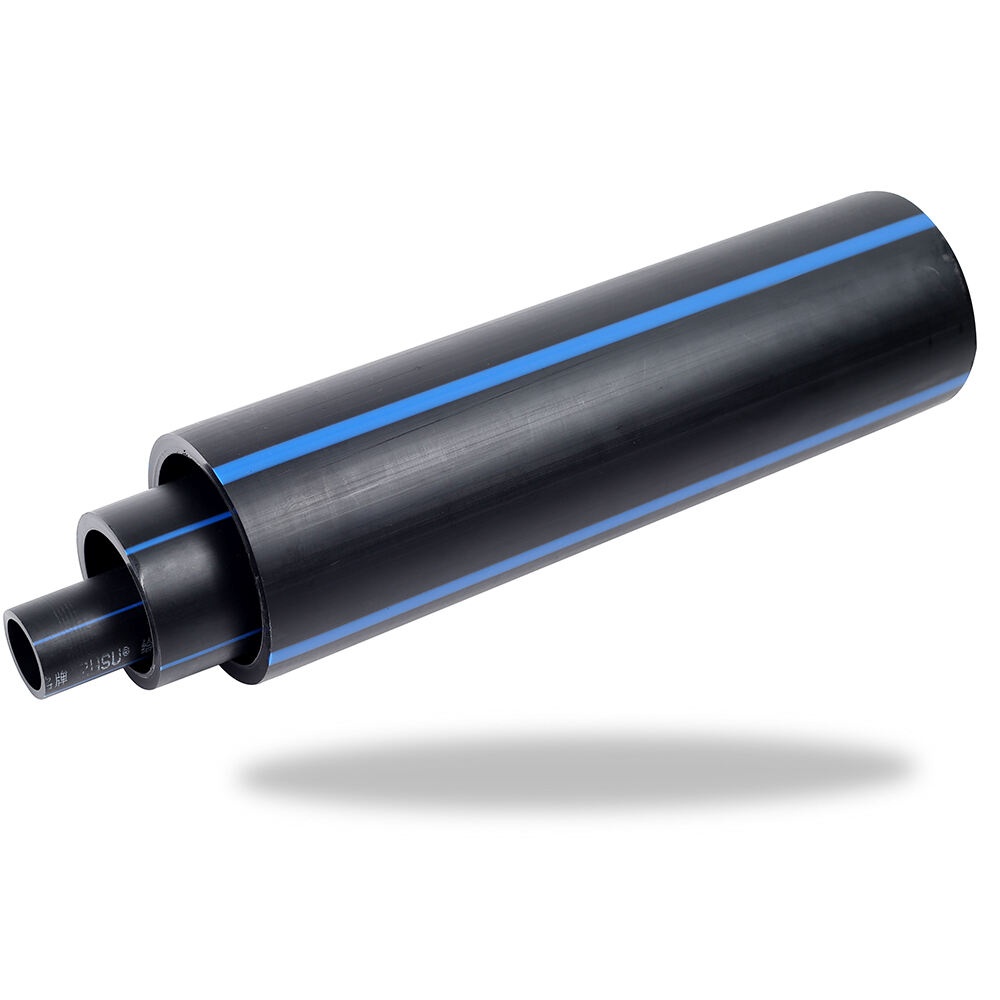

How the 100mm HDPE Pipe Serves Diverse Uses in Sewage and Drainage Systems

A great example of the 100mm HDPE pipe would be in sewage or drainage systems, itself a durable option not prone to succumb any damage on serious amounts of waste. It has powerful resistance to chemicals and UV-rays, protecting it from corrosion due high-risk situations for use with chemical compounds or waste.

One of the most advanced and efficient options for a number of industries, 100mm HDPE pipe is incredibly durable as well in addition to its other outstanding attributes. If you opt for a corrugated piping solution like this, thoughtfully created from recyclable materials then fitting can save enough money and also helps the environment. This smooth inner surface permits a faster rate of water and also squanderflow, calling for less energy to pump the waste with them Its production procedure is already so power reliable in manufacturing that it hardly requires extra heating entailing about 4 kwhr per day in typical family use as this does not involve heat searing. In all, 100mm HDPE pipes appear to be a dependable, effective and eco-friendly solution that can serve numerous purposes within the water management industry.

In 2004, with an authorized capital of 1.01 billion RMB, Shanghai Zhongsu Pipe Co., Ltd. is a manufacturer of a diverse selection of high-quality plastic pipes and fittings. Our range of products includes fittings and pipes made of PPR as well as antibacterial fittings and pipes as well as anti-UV fittings and pipes, PP RCT pipes and fittings, as along with HDPE fittings & pipes. We're dedicated to innovation and R&D, continuously enhancing our product range in order to meet the needs of changing times of our customers.

In Shanghai Zhongsu Pipe Co., Ltd., quality is the top priority. We are a CNAS-accredited national laboratory that conducts rigorous inspections during the entire production process. From raw material sourcing to the final product's delivery each stage adheres to international standards, such as ISO15874, ISO 16962, ISO 4427/4437 as well as DIN 8077/8078/8074/8075 etc. Therefore, our products are assured to be of the highest standards of safety and quality.

Shanghai Zhongsu Pipe Co., Ltd. is one of China's top ten companies and has been acknowledged as Shanghai's leading high-tech business. We are certified by CNAS approved Laboratory Certificate, ISO14001, ISO9001, ISO45001, CE-Certificate, and various CE Certificates for gas and water supply pipes. These distinctions demonstrate our commitment to achieving the highest quality in our production processes environmentally responsible practices and the safety of our products.

Our production facility is spread across 70,000 square meters in Jinshan District, Shanghai, equipped with world-class manufacturing lines as well as inspection equipment. With a capacity of 3,0000 tonnes that we can cater to a diverse customer base and offer quick delivery times, without compromising quality. We are delighted to have served over 3000 customers in the world, providing efficient piping solutions based on their particular requirements.